15 Apr Proper Tools – Drying Goals – Structural Dry-Out

Proper Tools to Determine Drying Goals and Progress During a Structural Dry-out

In order to reach drying goals after a water damage, a dry standard must be determined. To establish a dry standard, a moisture reading must be taken of unaffected material. Once all affected materials reach drying goals, the drying process is complete.

The best tools for determining drying goals and drying progress are relative moisture readings. There are several tools available for inspection and monitoring.

The most basic moisture detection instrument is the moisture sensor. This tool is used to detect high levels of moisture in the carpet and underlay. This is a sensor and not a meter; therefore, it will indicate the presence of abnormal moisture levels but a numerical value is not given by the device.

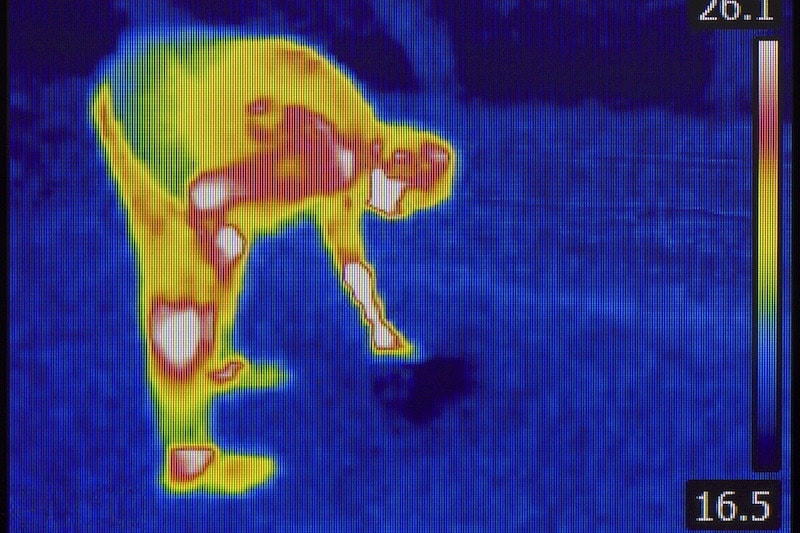

Surface temperature differences can be detected by thermal imaging cameras. A thermal imaging camera is used only to help identify “potential” moisture through evaporative cooling. Suspected areas should always be tested with a moisture meter to verify the readings.

An infrared thermometer is capable of reading surface temperatures of most material with direct contact. By measuring infrared light, readings can be acquired and will vary with the surface temperature of the material.

Moisture meters provide a numerical value for the moisture detected, unlike moisture sensors. The reading should be documented and used to monitor the drying progress. There are two different types of moisture meters, invasive and non-invasive. The type used will be determined by the various building materials to be tested.

Thermo-hygrometers are used to monitor any air that can influence the temperature and/or humidity within a restorative drying environment. They are used to verify equipment operation and to evaluate the need for additional equipment. They can be used to assist in strategic decisions as drying progresses toward the pre-determined dry standard.

When evaluating cavities within a structure that are obstructed, borescopes are very beneficial. Borescopes allow the user to see into wall cavities, beneath cabinetry, under tub enclosures, and into other hidden areas. A hole or opening of about ½” in diameter is required in order for the tip to be inserted and then the image is transferred to an eyepiece through a long, flexible neck using fiber optics.

When wanting to detect differences in air pressure between two spaces, a Manometer can be used. Air pressure differentials are particularly useful when working to contain high humidity or other contaminants, and/or to generate airflow in difficult to reach cavities.

Knowing which tool to use for each particular situation is imperative to complete the drying process by reaching the drying goals after a water damage. Only trust a professional to determine the dry standard, drying goals, and which tools to use to complete the process of drying the structure. Orange County Construction 911, has all of the appropriate tools and necessary knowledge to complete structural drying in a professional and timely manner.